Kelly Engineering Services

service

- maintenance contracts: preventative to proactive maintenance cycles

- installation, removal, upgrades, or parting out unused machinery

- machinery audits, including inspections, action reports and cost analysis

safety engineering:

- custom platforms

- railing systems

- protective guarding for units, folders and drivelines

repair (Goss single-wide presses)

- machinery repairs on folders

- printing units

- peripherals

training

- on-site training for new and under-trained employees

“Cal Poly motto “Learn by doing”

Ever since my college days I have accepted challenges and utilized my past skills, applied them to the present challenge, through teamwork and persistence met the criteria and completed the project with superior results.

What I did not understand, I asked questions, did independent research and consulted with experts in the field. It is amazing what people will offer if you just ask the question.”

Kelly Engineering Services

Project Management:

The ability to plan and coordinate all the elements from inception to completion, including bringing equipment on line and into full production. Identifying problems and creating solutions every step of the way. Providing training for the operators, proactive maintenance for maximum up-time, parts inventory for periodic maintenance and readily available consumables for operations.

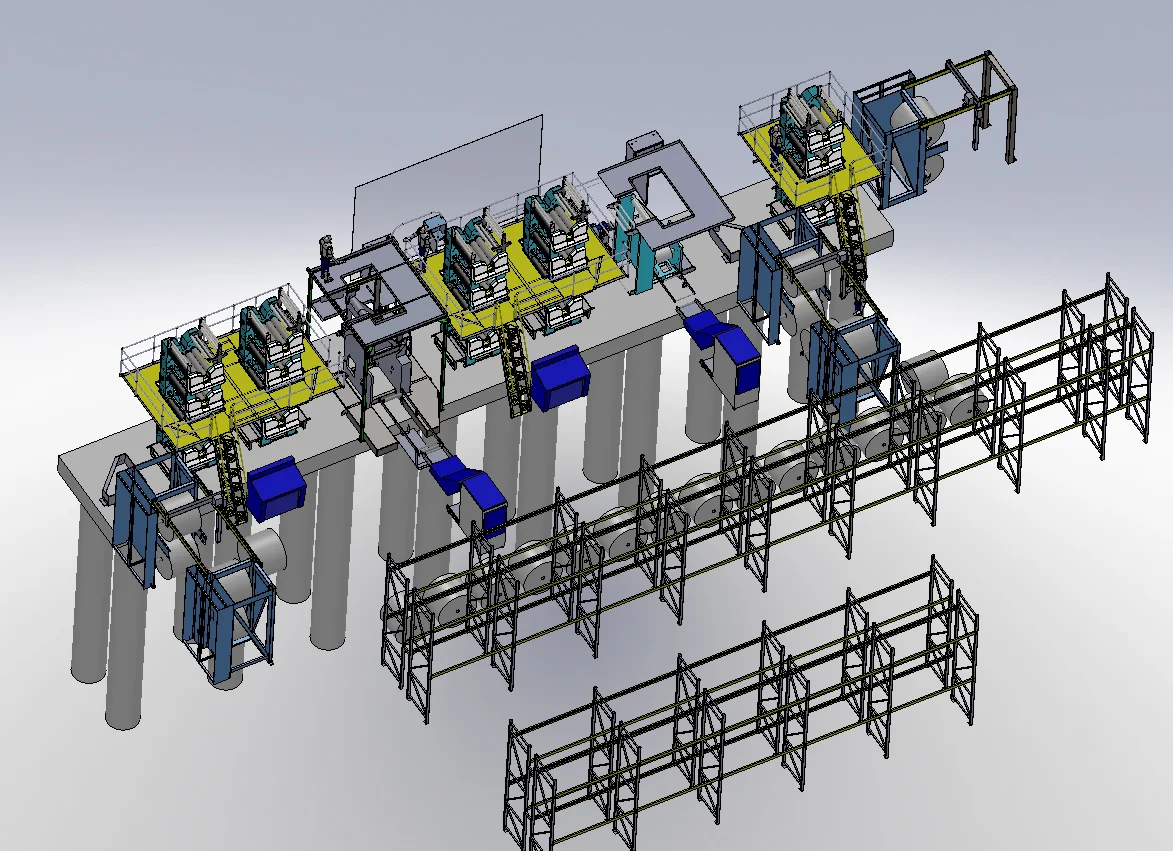

Engineering and Design:

A career in Web Offset printing has presented many challenges. In order for a company to be successful they need to meet every changing demands by customers in a sales driven environment. My responsibility has been to adapt, modify and enhance the production equipment to meet and exceed those demands cost effectively.

Purchased or acquired equipment had to be fitted to the existing machinery. I would engineer solutions, create the drawings, select vendors to manufacture or supply components, inspect and assemble components. This included mechanical drives, guarding, pneumatic and electrical controls.

Drawings are currently produced by building 3D models SolidWorks licensed software which is a highly effective way to produce products that fit the application first time.